Ultra Premium (UP) is a new category of olive oil that distinguishes the highest quality olive oil in the world. The UP standard was created in response to the growing need to separate high quality extra virgin olive oils from what dominates the so called “gourmet” and “premium” olive oil markets, as well as the broader category sold in mass markets the world over under thousands of brands and private labels. The absurdly low standards created and fostered by numerous trade associations and government agencies responsible for policing them has only contributed to the confusion and misinformation. EU producers are actually given a perverse incentive in the form of government subsidies to keep their oils in storage until market conditions improve. This practice clearly demonstrates the governmental complicity with retailers and bottlers to sacrifice quality for price. Lack of enforcement and testing by these trade associations and governmental agencies has led to a marketplace dominated by inferior oils and rife with adulteration. These practices by some of the world’s largest olive oil producers and bottlers have led to a steep decline in prices of extra virgin olive oil and are driving quality oil producers out of business.

The self serving overemphasis on “Where” extra virgin olive oil is produced continues to dominate perceptions at the expense of the far more significant “When, What, and How” the oil is made. The UP standard has as its principal barometers Chemistry and Freshness. These two underappreciated variables can be objectively measured, quantified, and certified. Since the highest quality EVOO comes from high quality fruit coupled with high quality production processes, the UP standard encompasses strict requirements for both the end-product and the production process.

No matter how high the quality of fruit and production methods used, the best olive oils in the world are never as good as when they are fresh. There are no standards for shelf-life of EVOO, and the current IOC “best buy” date is intentionally misleading and utilized at the whim of the retailer and bottler. When a quality EVOO is fresh, there is significantly more positive sensory attributes detectable by the palate. As any EVOO ages, it naturally oxidizes losing positive sensory qualities as well as inheriting defects. Newly developed tests can objectively quantify the “Freshness” of an EVOO at various stages in its lifecycle and are referred to as the “Fresh Pack” tests encompassing both the Diacylglycerol Content (DAGS) and Pyropheophytins (PPP).

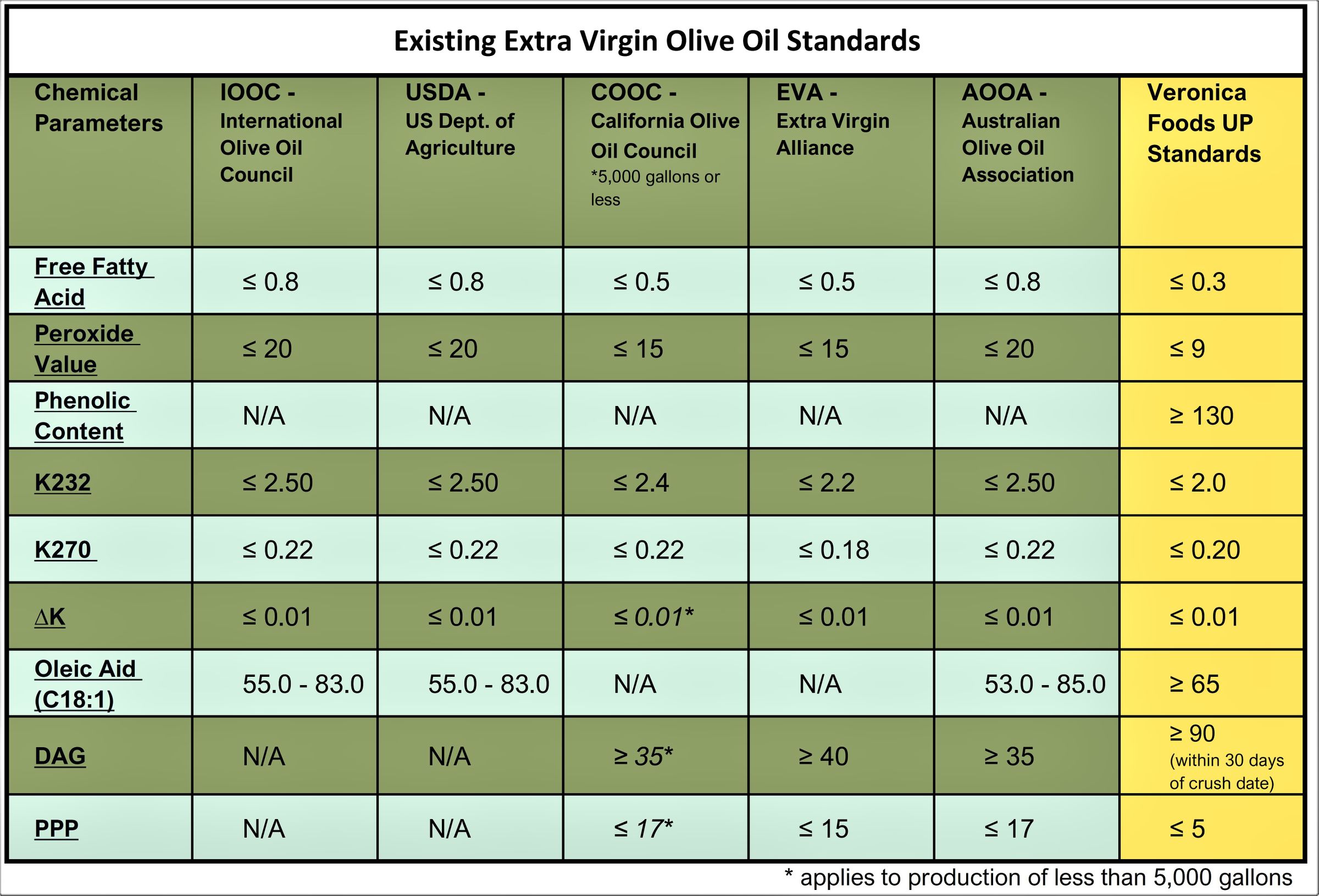

The UP standard is reserved for the finest extra virgin olive oils in the world, as such, the UP grade exceeds all existing European, Italian, Spanish, Greek, North American, Californian, or any other standard for the grade known as extra virgin olive oil. In order to qualify for the UP grade, the extra virgin olive oil must meet or exceed a comprehensive set of Production, Storage, Transportation, Testing, Chemistry, and Organoleptic requirements as set forth in the following document. Instead of placing an overemphasis on what is less important (Terroir) to the detriment of the most critical factors (Chemistry and Freshness), the UP program is intended to reward farmers for producing high quality oil. The UP program is intended to promote Fair Trade practices and help create a demand for a higher quality product thereby increasing the value.

How does the UP Program work? Candidate olive oils must provide a sample and agree to have the sample analyzed by an independent laboratory. The oils are tested to ensure that they meet or exceed the verifiable standards of the UP Program. Prior to purchasing an extra virgin olive oil for distribution, Veronica Foods Company requests a sample from the olive oil producer. The sample is sent to an independent lab where both a sensory and chemical analysis are performed to ensure that the oil meets or exceeds our exclusive UP® (Ultra-Premium) standard.

Do you test all brands? No. Only Extra Virgin Olive Oils being considered for the UP program and distribution by Veronica Foods are analyzed.

Does the fact that an olive oil does not have your seal mean that the olive oil is not authentic? No. The UP mark only identifies the highest quality extra virgin olive oils, distributed by Veronica Foods. Our goal is to identify the best olive oils on the market and ensure that they are offered for sale while they are fresh enough to have high levels of important nutrients. Even authentic olive oils may not qualify for the UP® mark.

Production Requirements

To ensure the highest level of quality olive oil is achieved, the highest quality fruit must be grown and the highest quality production processes utilized throughout the milling facility from beginning to end. These production requirements are based on prior results and therefore represent a set of best practices and guidelines for the farmer. The proof of these processes should be, but is not always, evident in the sensory and chemical analyses of the resulting olive oil.

| 3.1 General | |||

| 3.1.1 | Oil must contain 100% of content from olives | ||

| 3.1.2 | Must be estate produced or have complete traceability of each cultivar | ||

| 3.1.3 | Must list all variety or varieties of olives | ||

| 3.1.4 | Must display “Harvest” or “Crush” date | ||

| 3.1.5 | Cannot be more than 14 months old from Harvest/Crush date | ||

| 3.2 Farming | |||

| 3.2.1 | Sustainable farming practices must be employed | ||

| 3.3 Harvesting | |||

| 3.3.1 | Harvest at the optimum moment for quality not yield (can vary with cultivar, conditions, location, and fruit maturity index) | ||

| 3.4 Milling | |||

| 3.4.1 | Mechanical extraction using malaxer, centrifugation and decanter | ||

Storage and Transportation

Although the UP production process ensures quality fruit and quality processes, the EVOO must also be protected from environmental damage during all phases of storage and transportation from tree to bottle. The Fusti and Bottle storage requirements listed below specifically apply to all retail stores offering products carrying the UP Logo Certification.

| 4.1 Tank Storage | |||

| 4.1.1 | Inert Gas (Argon or Nitrogen)-lined at farm mill | ||

| 4.1.2 | Naturally settled at farm or lightly filtered as to not impact flavor or chemistry | ||

| 4.1.3 | Impermeable, stainless steel | ||

| 4.2 Bulk Containers | |||

| 4.2.1 | Air-tight seals | ||

| 4.2.2 | Temperature controlled | ||

| 4.3 Fusti Storage | |||

| 4.3.1 | No mixing of EVOOs | ||

| 4.3.2 | Fusti cleaning schedule | ||

| 4.4 Bottle Storage | |||

| 4.4.1 | Keep away from light and heat sources | ||

| 4.4.2 | Dark tinted glass bottles | ||

| 4.4.3 | Best when used within 4 months of first opening bottle | ||

Testing and Compliance

To ensure the highest standards are consistently being met and maintained, a comprehensive testing and compliance program has been developed for UP. From mill to bottle, these testing and compliance procedures mandate traceability and accountability in order to deliver the high standard of UP quality to the end customer.

| 5.1 Test Frequency | |||

| 5.1.1 | Initial Sample testing must be collected from numbered lot bulk storage and sent to third party testing facility to ensure compliance | ||

| 5.1.2 | Random Samples will be purchased anonymously from UP supplied stores and sent to a third party testing facility | ||

| 5.2 Testing Centers | |||

| 5.2.1 | All chemical testing and analyses must be performed at a third party certified laboratory | ||

| 5.2.2 | All UP olive oils must have a third-party Certificate of Authenticity (COA) on file with a certified laboratory | ||

| 5.3 Test Procedures | |||

| 5.3.1 | Test samples must follow a complete chain of custody to ensure integrity) | ||

| 5.3.2 | UP supplied stores will be audited randomly for storage, cleaning, and labeling practices as defined in the supplier agreement | ||

Third-Party Certified Laboratory used for UP Certification is Modern Olives

To achieve the highest standard in the olive oil industry, we use services of the most proficient olive oil lab by the American Oil Chemists Society standards

Chemistry

Objective, verifiable chemical standards form the foundation of the UP grade. Chemical analysis of EVOO has proven to be a fundamental indicator of sensory quality, predictor of perishability, and authenticity of olive oils. UP is the highest quality standard in the world because it utilizes the broadest array of available tests and enforces the strictest limits on all chemical standards.

Chemical Parameters |

Determination |

Indicators |

Extra Virgin Standard |

UP Standard |

| 6.1 Free Fatty Acids (FFA) | Free Fatty Acids are formed due to breakdown of the triacylglycerols in oils during extraction. Fatty acids are "free" when the are no longer bound to any other molecules. | An elevated level of FFA can indicate poor quality or mishandled fruit, too much time between harvesting and extraction, poor storage and/or high temperature during extraction. |

Units: % as oleic acid |

Units: % as oleic acid UP limit ≤ 0.3 |

| 6.2 Oleic Acid | The major fatty acid in olive oil triacylglycerols is Oleic acid making up 55 to 85% of olive oil | The higher the oleic acid monounsaturated fat content translates to increased durability and shelf-life. |

Units: % as oleic acid |

Units: % as oleic acid UP limit ≥ 65 |

| 6.3 Peroxide Value | Peroxides are primary oxidation products that are formed when oils are exposed to oxygen causing defective flavors and odors | Primary measurement of rancidity in oil. Higher peroxide levels indicate oxidized and/or poor quality oil & give an idea of the freshness & storage conditions. |

Units: mEQ O2/kg oil |

Units: mEQ O2/kg oil UP limit ≤9 |

| 6.4 UV Absorption | UV spectrophotometric determination Secondary measurement of rancidity in oil. Elevated levels of UV absorption indicate oxidized and/or poor quality oil, possible refining and/or adulteration with refined oil. | Secondary measurement of rancidity in oil. Elevated levels of UV absorption indicate oxidized and/or poor quality oil, possible refining and/or adulteration with refined oil. |

Units: K1%/1cm |

Units: K1%/1cm UP limits K232 ≤2.0 K270 ≤0.20, DeltaK ≤0.01 (immediately after production) |

| 6.5 Phenolic Content (Polyphenols) | Phenols are healthful anti-oxidant substances in olive oil which aid in slowing down the natural oxidative processes. | Phenolic content decreases over time and is an indicator of freshness, with higher amounts improving shelf-life and oxidative stability. | N/A | Units: (as ppm caffeic acid) UP minimum limit ≥ 130 |

| 6.6 DAGs | Fresh olive oil has a much higher proportion of 1,2-diacylglycerols to Total diacylglycerols while olive oil extracted from poor quality fruits and refined oils have a higher level of 1,3-diacylglycerols | The ratio of 1,2-diacylglycerols to the Total diacylglycerols are a useful indicator of fruit quality and acts as a snapshot of olive oil freshness. Low values can also indicate oxidized oil & sensory defects. | Units: %Total 1,2-diacylglycerols AOA limit≥35 |

Units: %Total 1,2-diacylglycerols UP limit ≥*90 (immediately after production) |

| 6.7 PPP | Upon thermal degradation of olive oil, chlorophyll pigments break down to pheophytins and then to pyropheophytins | The ratio of pyropheophytins to the total pheophytins is useful for distinguishing fresh olive oil from soft column refined, deodorized, or backblended oils. | Units: %Total Pheophytins AOA limit≤17 |

Units: %Total Pheophytins UP limit ≤5 (immediately after productio |

Organoleptic

The ultimate endpoint for Ultra Premium is to produce EVOO that has superior and distinguishable taste and sensory characteristics. Therefore, all Ultra Premium EVOOs must pass a panel of skilled tasters, not only being free from defects, but also possessing measurable bitterness, pungency, and fruity qualities.

| 7.1 Taste Panel | |||

| 7.1.1 | The Taste Panel must be an industry recognized or certified sensory panel | ||

| 7.1.2 |

Panel testing must find that the median of defects = 0 and possess the following minimum sensory evaluation scores: |

||

HERE IS MORE INFORMATION ON THE CHEMISTRY OF EXTRA VIRGIN OLIVE OIL AND HOW IMPORTANT IT IS FOR YOU TO KNOW WHAT YOU ARE PURCHASING.

Free Fatty Acids - FFA

Indicates the condition of the olives at time of crush! Healthy fruit, processed immediately should produce oil with low FFA!

The lower, the better! An oil with a low (FFA) will have a higher smoke point than an oil with a higher FFA.

The IOC requires that this number be below 0.8 in order for an olive oil to be considered Extra Virgin grade.

Peroxide Value - PV

This number must be equal to or less than 20. This is the primary measurement of the rancidity of a particular extra virgin olive oil. Peroxide value is affected by procedures used in processing and storing of the oil. Peroxide is responsible for color and aroma changes as the oil oxidizes.

Oleic Acid

Oleic Acid- A higher level is better! Oleic acid is responsible for some of the health benefits of EVOO, and its high resistance to free radicals helps to slow down the spread of damaging chemical chain-reactions. Because of its high degree of resistance to attack by oxygen free radicals, higher levels of oleic acid in an olive oil help keep it fresher for longer, by preventing the formation of peroxidized (rancid) fats.

Our bodies absorb any peroxidized fats that we consume and incorporate them into our cells. Oleic acid’s superior resistance to free radical attacks protects our cell membranes, proteins, and DNA from being damaged, as it protects the oil from spoiling.

Substituting oleic acid for saturated fatty acids in animal fats improves cholesterol balance,[i] and research also suggests that oleic acid may have more specific health benefits, such as the ability to help regulate healthy blood pressure by altering cellular signaling.[ii],[iii],[iv],[v] For these and other reasons, the US FDA has approved the health claim that “Limited and not conclusive scientific evidence suggests that eating about 2 tablespoons (23 grams) of olive oil daily may reduce the risk of coronary heart disease due to the monounsaturated fat in olive oil.”

Biophenols Profile

As science developed, we have learned that a significant amount of health attributes related to extra virgin olive oil are not only linked to its profile rich in monounsaturated fatty acids but also to its biophenol content. In the early days, total biophenol content was simply measured by measuring the reaction of this complex group of substances with a colorant (Folin-Ciocalteau).

The darker the blue colour developed from the reaction, the higher the level of biophenols. The actual level of biophenols was determined by a comparative scale measuring how much colour was developed by known quantities of a standard phenol (either caffeic acid or garlic acid). Even when this method provided a reasonable indication, it was far from perfect as all different phenols react to the colorant in different ways. Furthermore, it did not tell us anything about the different groups of biophenols. As we know now, some of those biophenols have very specific health and sensory properties (i.e. Oleocanthal, which has important antinflammatory action and it is responsible for the pungent feeling on the back of the throat).

Even when there are no limit for polyphenols in international standards, they are very effective antioxidants in olive oil and contribute significantly to oxidative stability, shelf life and health claims. Given the growing importance of these antioxidants, a new and more precise measuring method has been developed. This method utilises High Performance Liquid Chromatography (HPLC). High Performance Liquid Chromatography (HPLC) is a form of column chromatography that pumps a sample mixture or analyte (in this case EVOO) in a solvent (known as the mobile phase) at high pressure through a column with chromatographic packing material (stationary phase). The sample is carried by a moving carrier gas stream of helium or nitrogen. HPLC has the ability to separate, and identify compounds that are present in any sample that can be dissolved in a liquid in trace concentrations as low as parts per trillion. Sample retention time (the time that it takes for each biophenol to exit the column) will vary depending on the interaction between the stationary phase, the molecules being analyzed, and the solvent, or solvents used. As the sample passes through the column it interacts between the two phases at different rate, primarily due to different polarities in the analytes. Analytes that have the least amount of interaction with the stationary phase or the most amount of interaction with the mobile phase will exit the column faster. A detector at the point of exit determines when and how much of each biophenol is sensed. The total amount of biophenols in this method is determined by adding the individual quantities of each measured biophenol.

There are typically more than 20 different biophenols in extra virgin olive oil. The prevalent classes of hydrophilic phenols found in EVOO are phenolic alcohols and acids (i.e. Hydroxytyrosol and vanillic acid), flavonoids (i.e. luteonin), lignans (i.e. pinoresinol) and secoiridoids. Among these substances the last two classes include the most concentrate phenols of EVOO. Secoiridoids, like aglycone derivatives of oleuropein, demethyloleuropein and ligstroside, are present in olive fruit as most abundant EVOO phenolic antioxidants. Several important biological properties (antioxidant, anti-inflammatory, chemopreventive and anti-cancer) and the characteristic pungent and bitter tasty properties have been attributed to EVOO phenols.

Leandro Ravetti

Technical Director - Boundary Bend

Phenols

Antioxidant like substances that are naturally occurring in Extra Virgin Olive Oils. Phenols extend the shelf-life of extra virgin olive oil & also determine the “style” in terms of bitterness and pungency. Generally, when an oil has a high phenol count (presented in parts per million), it will have more “pepper” or more “bitterness”. Many consider phenols to be free-radical “scavengers”.

Studies show a dose-dependent & significant effect of olive oil Phenol consumption (for 3 weeks) on appropriate markers of LDL peroxidation

European Food Safety Authority) “Consumption of olive oil phenols contributes to the protection of blood lipids from oxidative damage.”

Religiously consumed by the "Life Extension Community" and have been featured in several recent health studies!

Alpha-tocopherols are Pro-Vitamin E compounds that are essential in the control of LDL that generates cholesterol.

DAGs (Diacylglycerols)

DAGs are always reported & presented in the1,2 ratio (as a percentage of total DAGs) as the oil ages, the 1,2 DAGs are transformed to 1,3 DAGs

Fresh Olive Oil made from sound fruit should result in a DAG content of 85% or higher whereas the processing of rotten and or fermented olives will produce fresh oil with low DAGs indicating a very short shelf-life.

DAGs typically drop between 20-30% per year depending on storage conditions and FFA. They are highly influenced by heat but not light.

DAGs are important shelf-life indicators and can be used to determine the shelf life (or lack thereof) of an oil at any time in its life.

Recent studies show that many grocery store oils fail DAGs (35% is considered falling in the voluntary Australian standard) which shows a high correlation with sensory defects, more so than any other test.

The degradation of DAGs (rate) are highly predictable over time if initial quality (FFA) is known and storage conditions.

(PPP) Pyropheophytin A

Chlorophyll degradation Products in Olive Oil

Most sensitive method (ratio) able to detect the presence of deodorized (soft-column refined, thermally treated) oils

Recent studies show that many grocery store oils fail PPP (17% is considered falling in the voluntary Australian standard)

Freshly made oil should have a PPP of close to zero.

Soft column refining is generally used to strip out sensory defects and otherwise neutralize some chemical parameters in old oils or oils made from over-ripe and fermented (late season) olives so that they can pass typical authenticity tests, undetected.

PPP are highly influenced by heat and then also by light.

In ideal storage conditions, they should only increase between 6-8% per year! An oil with an extremely high PPP is a clear indication that “something” is wrong or amiss. Either the oil is severely aged, deodorized or has had continuous light exposure (clear packaging!) for extended time periods and/or higher than normal storage temperatures.

A-Tocopherals

A nutrient that the body needs in small amounts to stay healthy and work the way it should. It is fat-soluble (can dissolve in fats and oils) and is found in seeds, nuts, leafy green vegetables, and vegetable oils. Alpha-tocopherol boosts the immune system and helps keep blood clots from forming. It also helps prevent cell damage caused by free radicals (highly reactive chemicals). Alpha-tocopherol is being studied in the prevention and treatment of some types of cancer. It is a type of antioxidant. Also called vitamin E.

Squalene

Squalene is a natural organic compound which is part of our tissues. It is a polyunsaturated hydrocarbon, its molecular structure resembles that of vitamin E. However Squalene contains four additional groups of isoprenoids, which are very potent natural antioxidants.